As a scaffolding welding machine supplier, I often encounter customers who are concerned about the replacement cost of parts for these machines. Understanding the factors that influence these costs is crucial for both maintaining the machines effectively and making informed purchasing decisions. In this blog, I'll delve into the details of what determines the replacement cost of scaffolding welding machine parts and provide insights to help you manage your equipment more efficiently.

Types of Scaffolding Welding Machines and Their Parts

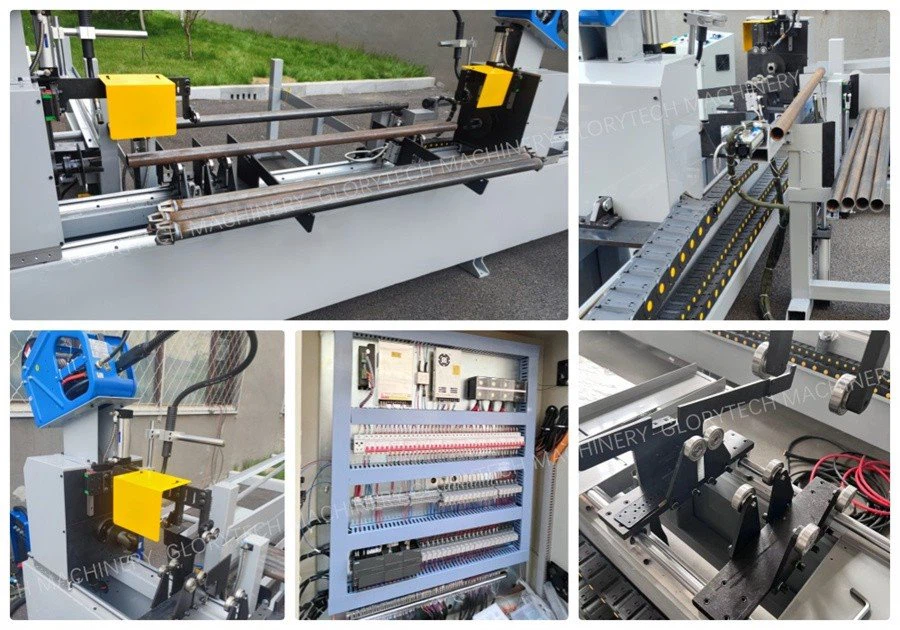

There are several types of scaffolding welding machines, each designed for specific tasks in scaffolding production. For example, the Ringlock Ledger Welding Machine is specialized in welding ringlock ledgers, while the Cuplock Ledger Welding Machine is used for cuplock ledger welding. The Scaffolding Pipe Welding Machine is designed to weld pipes for scaffolding structures.

Common parts in these machines include welding electrodes, wire feeders, power supplies, control panels, and mechanical components such as gears and bearings. Each part plays a vital role in the machine's operation, and their replacement costs can vary significantly.

Factors Affecting the Replacement Cost of Parts

1. Material Quality

The quality of the materials used in the parts has a direct impact on their cost. High - quality materials, such as premium steel for gears or advanced alloys for welding electrodes, are more expensive. These materials offer better durability, higher performance, and longer service life. For example, a welding electrode made from a high - quality alloy can withstand higher temperatures and produce better welds, but it will cost more than a standard electrode.

2. Manufacturing Complexity

Parts that are complex to manufacture will generally have a higher replacement cost. Components with intricate designs, precise tolerances, or specialized manufacturing processes require more time, labor, and advanced machinery to produce. For instance, a custom - designed control panel with advanced programming and multiple functions will be more expensive than a simple on - off switch due to the complexity of its manufacturing.

3. Brand and Supplier

Well - known brands often charge a premium for their parts. This is because they have established a reputation for quality and reliability. However, it's not always necessary to choose the most expensive brand. There are also many reliable suppliers that offer high - quality parts at a more competitive price. As a supplier, I always strive to provide a balance between quality and cost, offering parts that meet industry standards at reasonable prices.

4. Availability

The availability of parts can also affect their cost. If a part is rare or in short supply, its price will likely be higher. This could be due to limited production, high demand, or supply chain disruptions. For example, during a global shortage of certain electronic components, the replacement cost of parts containing these components in scaffolding welding machines increased significantly.

Estimating Replacement Costs

Welding Electrodes

Welding electrodes are one of the most commonly replaced parts in scaffolding welding machines. The cost of welding electrodes can range from a few dollars to several tens of dollars per kilogram, depending on the type and quality. For example, mild steel electrodes are relatively inexpensive, while stainless steel or aluminum electrodes are more costly.

Wire Feeders

Wire feeders are essential for continuous welding operations. The replacement cost of a wire feeder can vary from a few hundred dollars for a basic model to over a thousand dollars for a high - end, precision wire feeder with advanced features such as variable speed control and automatic wire tension adjustment.

Power Supplies

Power supplies are the heart of the welding machine. A standard power supply for a small - to - medium - sized scaffolding welding machine can cost anywhere from $500 to $2000. However, larger, more powerful power supplies with advanced features like inverter technology and multiple output settings can cost several thousand dollars.

Mechanical Components

Mechanical components such as gears and bearings also need to be replaced periodically. The cost of a gear or bearing depends on its size, material, and quality. A simple bearing might cost around $10 - $50, while a large, high - precision gear could cost several hundred dollars.

Strategies to Reduce Replacement Costs

Regular Maintenance

One of the most effective ways to reduce replacement costs is through regular maintenance. By keeping the machine clean, lubricated, and properly calibrated, you can extend the lifespan of its parts. For example, regular cleaning of the wire feeder can prevent clogging and reduce the wear on its components, thus delaying the need for replacement.

Training Operators

Properly trained operators are less likely to cause damage to the machine's parts. Training should include correct operating procedures, safety protocols, and basic troubleshooting. For instance, an operator who knows how to set the correct welding parameters will reduce the stress on the welding electrodes and other components, leading to lower replacement costs.

Buying in Bulk

As a supplier, I offer discounts for bulk purchases of parts. Buying parts in larger quantities can significantly reduce the per - unit cost. This is especially beneficial for customers who operate multiple scaffolding welding machines or have a high - volume production environment.

The Importance of Understanding Replacement Costs

Understanding the replacement cost of parts in scaffolding welding machines is essential for budgeting and cost - control. By having a clear idea of the potential costs, you can plan for part replacements in advance and avoid unexpected expenses. It also helps you make more informed decisions when purchasing a new machine, as you can consider the long - term cost of maintaining and replacing its parts.

Conclusion

In conclusion, the replacement cost of parts in scaffolding welding machines is influenced by various factors, including material quality, manufacturing complexity, brand, and availability. As a supplier, I am committed to providing high - quality parts at competitive prices and offering guidance on how to manage replacement costs effectively. Whether you are a small - scale scaffolding producer or a large - scale industrial manufacturer, understanding these costs is crucial for the efficient operation of your business.

If you are interested in learning more about our scaffolding welding machines or the replacement parts we offer, please feel free to contact us for a detailed discussion. We are here to help you find the best solutions for your scaffolding production needs.

References

- Welding Handbook, American Welding Society

- Machinery's Handbook, Industrial Press

- Scaffolding Industry Standards and Guidelines, International Scaffolding Association